Sometimes bad news is good news. Case in point: the current slowdown in U.S. auto manufacturing caused by the global semiconductor shortage.

Since Jan. 1, several GM and Ford assembly plants in the Midwest have been idled given a dearth of microchips, and their workers put on partial-pay. In contrast to the uptick of positive economic and employment data reported for February and March, the recent pause in auto-making, despite surging domestic demand, appears at first glance like a spate of very bad news for the Biden Administration, given its eagerness to move the U.S. economy into the fast lane by early summer.

The ongoing micro-chip shortage, in point of fact, presents President Biden with a golden opportunity to prove his industrial policy chops in a region where a tangible win would pay the biggest future electoral dividends: the U.S. Upper Midwest. Greymantle calls it ‘Joe Biden’s supply chain opportunity’.

A CHANCE TO REBUILD NOT ONE, BUT TWO BASES

Hard-pressed Michigan and Wisconsin auto workers played a prominent role in both Donald Trump’s and Joe Biden’s election victories in 2016 and 2020, respectively. Ending the chip shortage and restoring auto production would boost Biden’s reputation as a problem-solver for blue collar workers, putting paid to the accusation that he is nothing but a Beltway windbag whose pledge to lead a manufacturing revival is just hot air.

The incoming administration seems to realize its opportunity. Back in February, President Biden issued an executive order mandating that all U.S. government agencies commence a 100-day review of their supply chains, along with an analysis of supply chain vulnerabilities in the U.S. as a whole. The agency reviews will be completed by late May.

The executive order also mandated a second, more in-depth review of U.S. supply chain vulnerabilities scheduled to last for one year. This second review will be complete in 1Q22 and will give the administration the chance to propose a combination of broad tax incentives and cash subsidies for key U.S. industries if they commit to moving production facilities for key goods (e.g. pharmaceuticals, auto parts, electronic components) back to the United States from overseas factories.

In short, President Biden is creating the policy conditions necessary to follow through on both his and his immediate predecessor’s promise to “bring American manufacturing back home”.

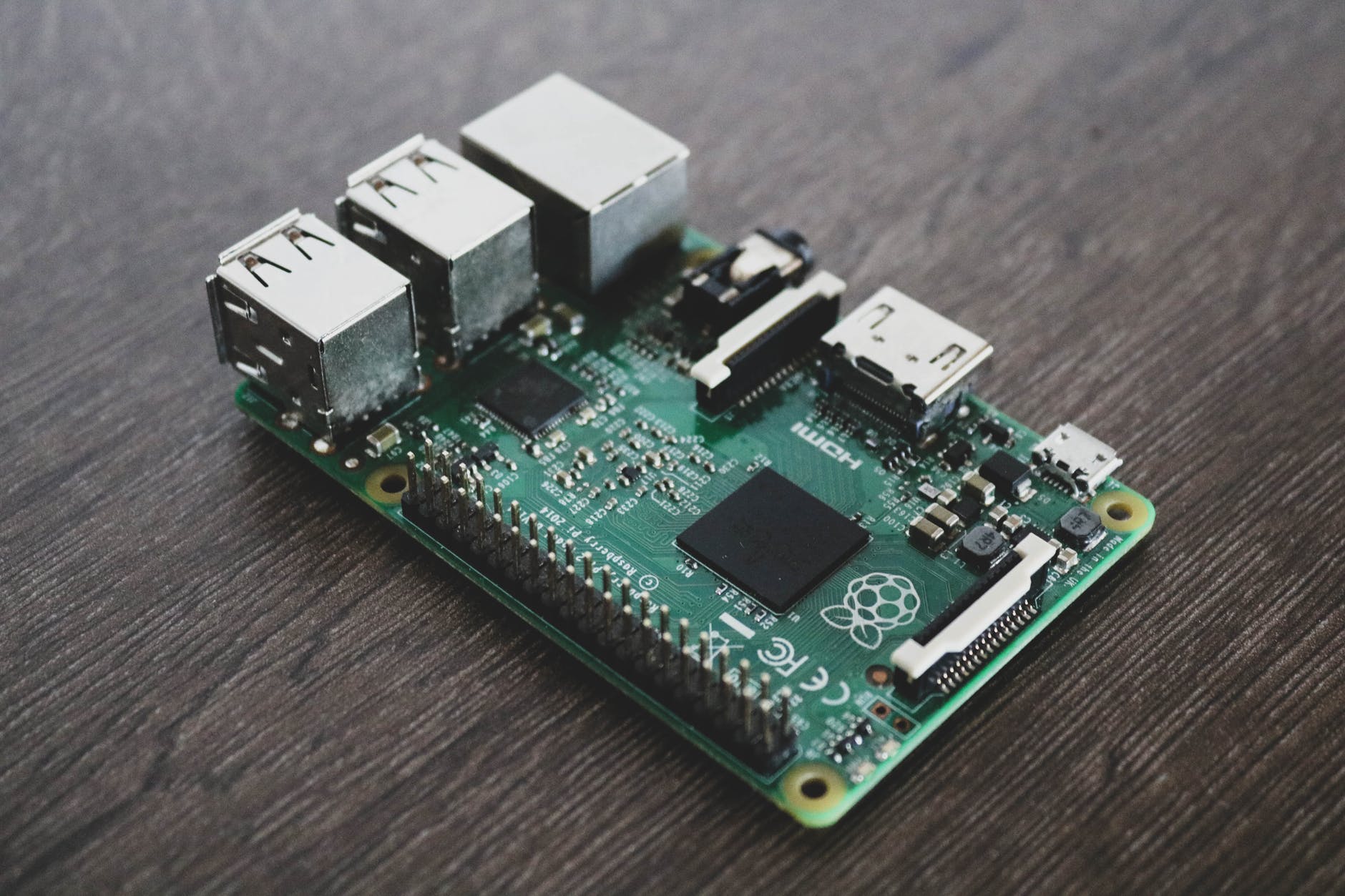

Biden isn’t overlooking the need to invest in R&D, either, which will boost his policy’s chances of long-term success. The American Infrastructure Plan (AIP), Mr. Biden’s second, multi-trillion dollar stimulus initiative following March’s American Rescue Plan Act (ARPA), includes $50 billion of proposed new research & development spending focused exclusively on the domestic semiconductor industry. The aim appears to be an expansion of U.S. semiconductor production to lessen domestic industries’ reliance on the vastly complex Asian semiconductor supply chain.

The AIP’s $50 billion proposal comes not a moment too soon: U.S. industry has never been more vulnerable to the risk of deliberate disruptions in global semiconductor supplies by foreign adversaries.

THE STUFF OF NIGHTMARES

The American automotive and high-tech industries remain highly dependent on the operations of a single Taiwanese micro-chip maker: Taiwan Semiconductor Manufacturing Company (TSMC). Taiwan is presently in the midst of its most serious drought in decades, which, along with 2020 production slowdowns caused by the pandemic, have turned TSMC into a major bottleneck for semiconductor production.

While TSMC has pledged $21 billion of new investments in 2021 alone to increase its chip-making capacity, these investments will take 2-3 years to come online, leaving the likes of GM, Ford and Toyota (both its Japanese and U.S. operations) vulnerable to continued chip shortages.

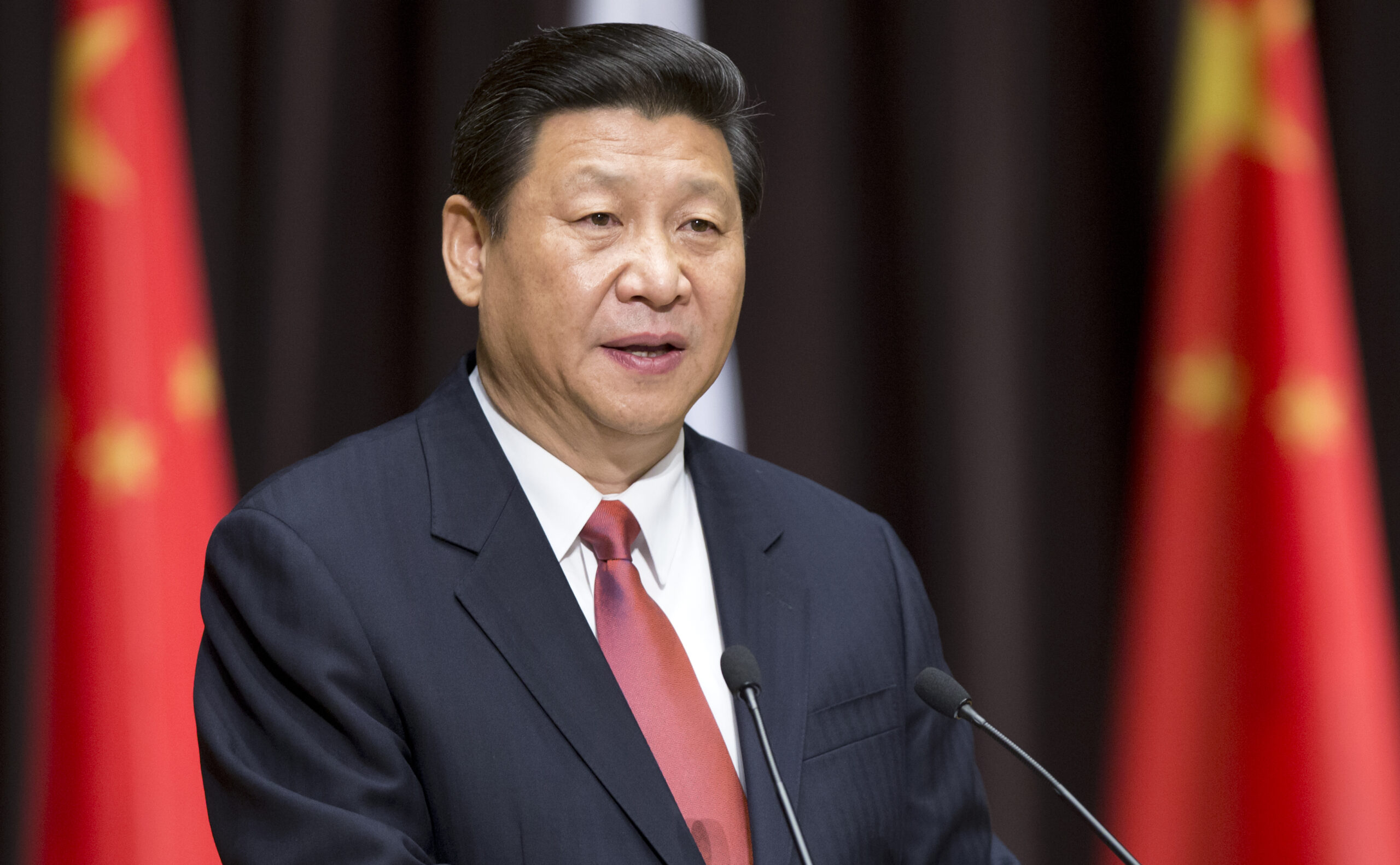

These facts don’t even begin to consider TSMC’s geo-strategic vulnerabilities linked to rising tensions between the U.S. and China, and between China and Taiwan. To put it bluntly: a Chinese blockade of Taiwan that included as one of its aims the strangling of U.S. smart phone, consumer electronics and auto production is the stuff of nightmares.

The U.S. clearly needs to build out its native semiconductor manufacturing capacity between now and 2024. A 25% to 30% capacity boost by the likes of Global Foundries, Intel and Micron Technologies might seem exceptionally ambitious (and indeed no one has publicly suggested that such a target is either desirable or reachable). But President Biden may want to consider doubling the AIP’s investment to $100 billion to reach that or a similar goal.

THE WATER OF LIFE

It is worth pointing out that the key natural resources required to manufacture semiconductors — aside from silicon — are exceptionally clean fresh water and reliable electricity. The Upper Midwest of the U.S. is abundant with both of these resources, given that the states of Illinois, Indiana, Michigan, Minnesota, Ohio and Wisconsin are graced with a vast supply of fresh water due to their proximity to the Great Lakes.

The Great Lakes and St. Lawrence River also border upstate New York, New Hampshire and Vermont, areas which are already home to a fair amount of domestic semiconductor production (Global Foundries’ operations near Burlington, VT immediately come to mind). Ohio likewise generates considerable hydro-electrical power through its complex river system and remains home to a large share of U.S. auto manufacturing.

To build up U.S. semiconductor manufacturing across this region while supporting domestic auto production and driving manufacturing of next generation smart phones, driverless cars and military technologies seems like a sensible industrial strategy. As an electoral strategy to win back their traditional blue collar constituencies for the Democratic Party, it would also make a great deal of political sense for Mr. Biden.

A FRAGILE WEB

The pandemic has highlighted the Western World’s vulnerability to overstretched supply chains by snarling air and shipping routes globally. Idled auto production lines and dozens of ships waiting to be unloaded outside the Ports of Los Angeles and Long Beach are just the most visible manifestations of the underlying illness: the U.S. and other Western nations have become far too dependent on imported goods made elsewhere and sourced through just-in-time-management of supply chains.

Automobile parts, semiconductors, personal protective equipment, over-the- counter drugs…the list goes on and on. Back in the 1990s, economists focused on the short-term benefits of globalization touted the virtues of efficiency and the lower costs of sourcing goods from abroad. The pandemic has laid bare the brittle nature of this web – it’s extreme vulnerability to the sudden shocks brought on by wars, financial crisis and new diseases.

If Donald Trump got one thing right – and it was probably the only thing he got right – it was his instinctual understanding that America’s economic dependence on foreign powers, and rising adversaries in particular, represents a profound danger to our nation’s economic health and stability. He also understood that the hour was later than most of us had suspected.

Joe Biden’s understanding of this dilemma appears to have been altered by both the rise of Mr. Trump and by the pandemic itself. Though Mr. Biden had long been comfortable in the center of his party, the early, radical actions of his administration suggest a profound shift in Biden’s perspective. In the president’s early actions and executive orders the economic, political and cultural appear to be one. There is a new kind of holistic thinking in evidence in the administration’s method.

Mr. Biden appears alert to the opportunities of the moment. For his sake and ours, let’s hope he takes full advantage of all they have to offer.

Until next time, I remain –

Greymantle